What We Offer

Polymer compounding & recycling, rubber reprocessing and tolling are the main activities and services that we provide at our manufacturing sites. We take pride in working closely with our customers to deliver the products that they need, when they need it.

Experts in Plastic Compounding

Ravago Manufacturing Europe’s core activity is enhancing the performance and/or aesthetics of polymers through compounding. So what exactly is compounding? It’s the process of producing a plastic formulation that combines resin(s), fillers and additives to achieve specific material properties.

Fillers are used to find the right balance of characteristics such as stiffness, shrinkage, impact resistance and opacity. The most common types of fillers used are glass fibers, glass beads, talc, calcium carbonate and barium sulfate

Additives are also used to adapt the properties of the plastic, this can be for example to extend their lifetime, improve their durability, make them easier to process, or for safety and standard compliance. Commonly used additives are UV stabilizers, heat stabilizers, flame retardants, anti-static agents, mold release additives and color pigment.

Blending of polymer resins is also possible; combining PA and ABS to create PA/ABS, including other polymers to modify impact, or improving recycled content of compounds.

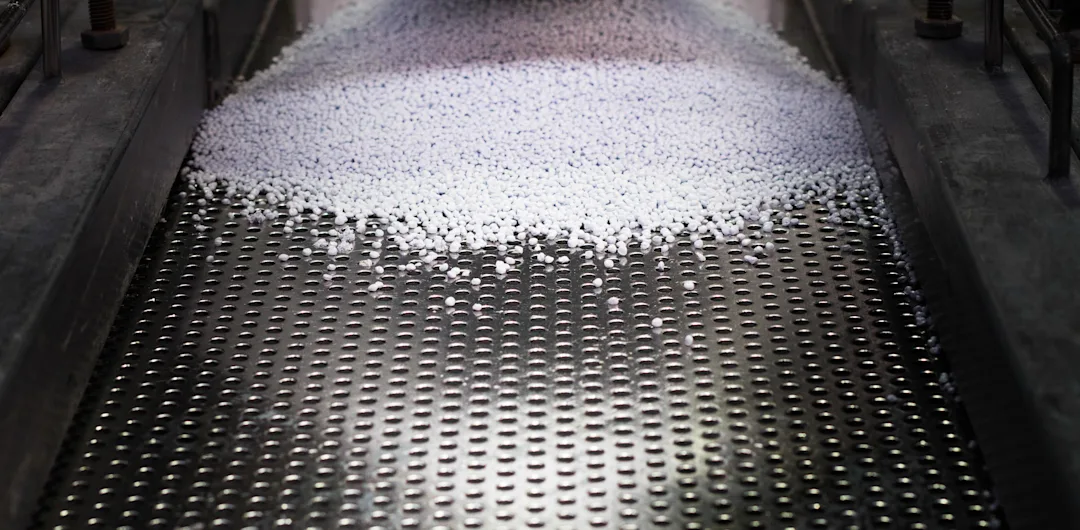

Plastic Compounding Process

In the compounding process, additives and fillers are added to the molten polymer resin, mixed together homogeneously in an extruder by the screw(s), extruded and pelletized to produce the final plastic compound. This compound can then be used directly by plastics converters in their own manufacturing processes, such as injection molding, extrusion, blow molding or thermoforming.

At our manufacturing sites across Europe, our technical experts develop formulations to produce a wide range of plastic compounds from polyolefins, engineering thermoplastics and thermoplastic elastomers.

Our extensive laboratory capabilities also enable us to develop and test the material properties and mechanical performance of our compounds to ensure that they meet customer requirements.

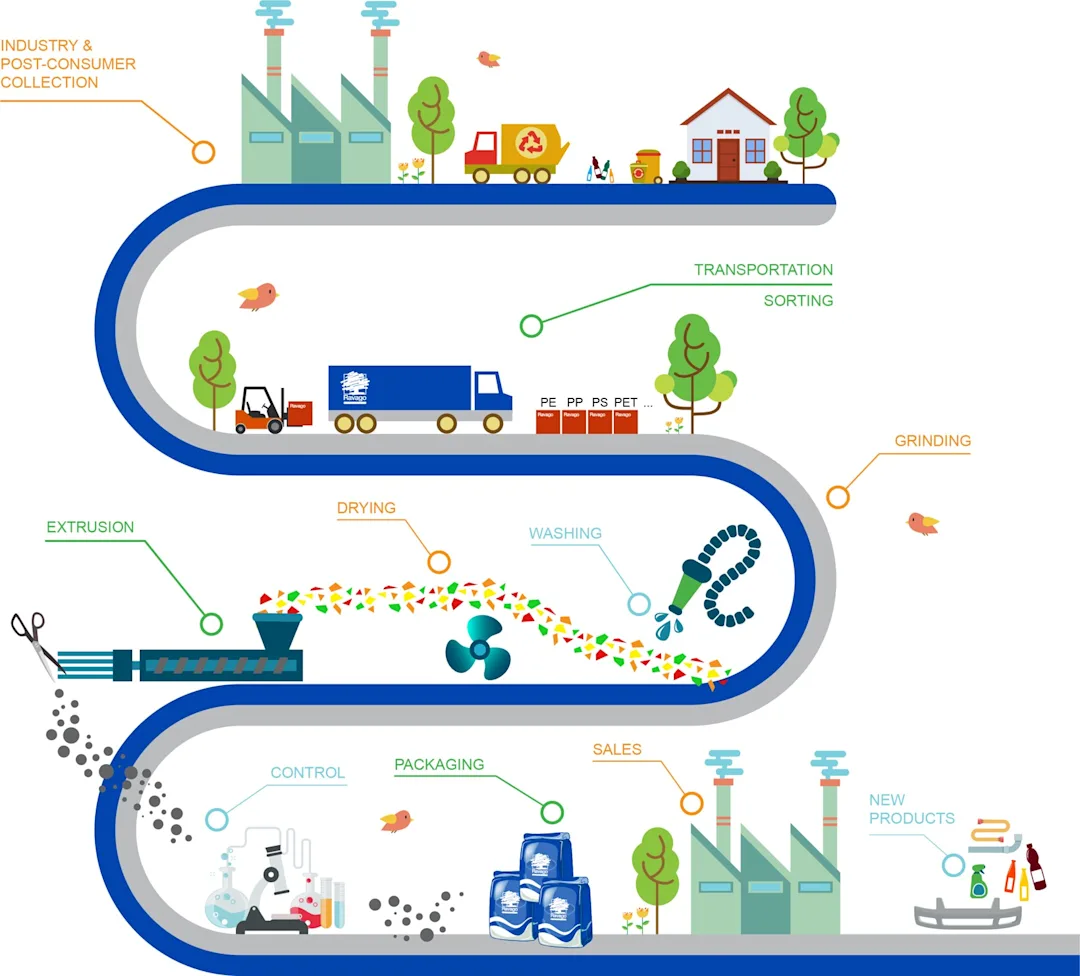

Recyclers for Over 60 Years

We have a strong heritage in recycling and turning waste that would otherwise be sent to landfill, be incinerated or end up in the environment, into reusable materials that have a second life.

We mechanically recycle many different polymer types at our plant including polyamide (PA6 & PA66), polypropylene (PP), polyethylene (LDPE & HDPE), polystyrene (PS), polycarbonate (PC), acrylonitrile butadiene styrene (ABS) and polyethylene terephthalate (PET). We source a wide variety of post-industrial and post-consumer feedstocks such as carpets, textiles, packaging films, rigid packaging waste and lumps from the resin production process. These feedstocks are then transformed through specially designed processes that shred, wash, melt, compound and extrude them to produce plastic granules.

Our customers can either use these polymer compounds directly in the plastic conversion process to maximize the recycled content, or blend them with virgin polymers to achieve specific performance or aesthetic requirements.

Rubber Reprocessing

Ravago is a world leader in rubber reprocessing, and annually recycles thousands of tonnes of uncompounded and unvulcanized synthetic rubber scrap from the petrochemical industry to produce our Ravaflex™ product range. Our unique and specially developed process ensures that we deliver reliable and consistent quality products to our customers. The entire Ravaflex portfolio is certified as 100% recycled.

Your Partner for Tolling Services

Do you need to access to extra production capacity? Or do you not have the in-house expertise or equipment to recycle or produce the plastic compounds that you need? We have many years of experience in providing toll compounding and recycling services to many satisfied customers in the polymers industry. With our formulation know-how and manufacturing flexibility, we can deliver the products you need, when you need them.

Why toll manufacture with us?

There are many reason why our customers choose to work with us:

- Assured confidentiality

- Option to establish a compounding contract

- Diverse range of services to respond to your specific business needs

- Processing capability for a full range of thermoplastics, reinforcements, fillers, additives and colors

- Wide range of analytical and research capabilities

Contact us today to learn more about how our tolling services could support your business.